Phone/Whatsapp:+86-13269138880; 15010322402 E-mail:info@dc-graphite.com

Open Nav

- Home

- About

- Products

- Graphite raw materialsCarbon/Graphite FeltHard Composite (PAN)Carbon felt/(PAN)Graphite Felt

- Graphite product

- Graphite mold for Continuous Casting brass/copper

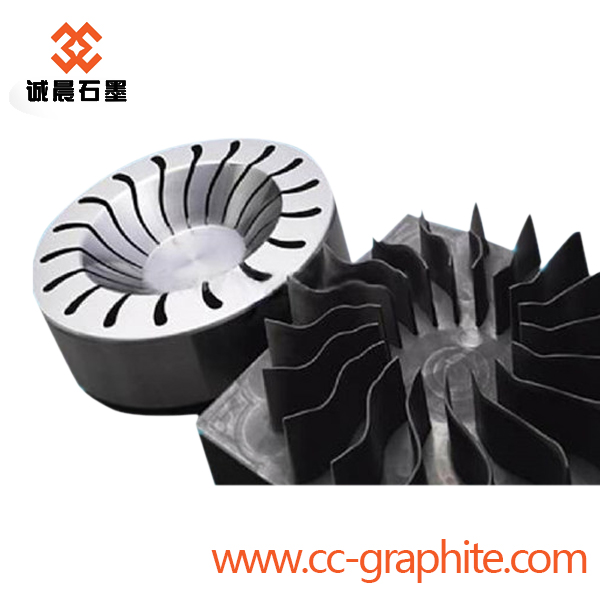

- Graphite rotor for Alumimum industry

- Vaccum Furnace,Sintering and Quartz Glass Industry

- pyrolytic graphite

- AAS graphite tube

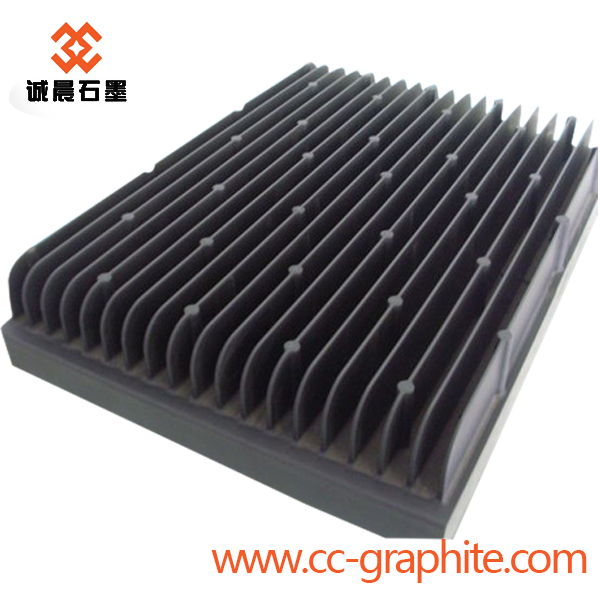

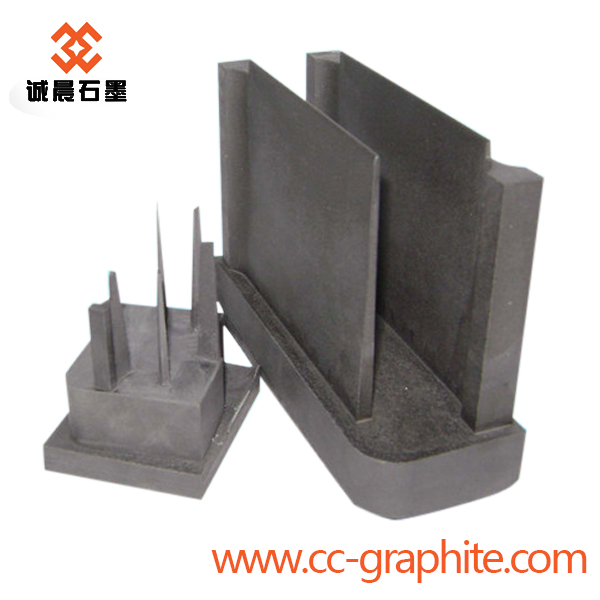

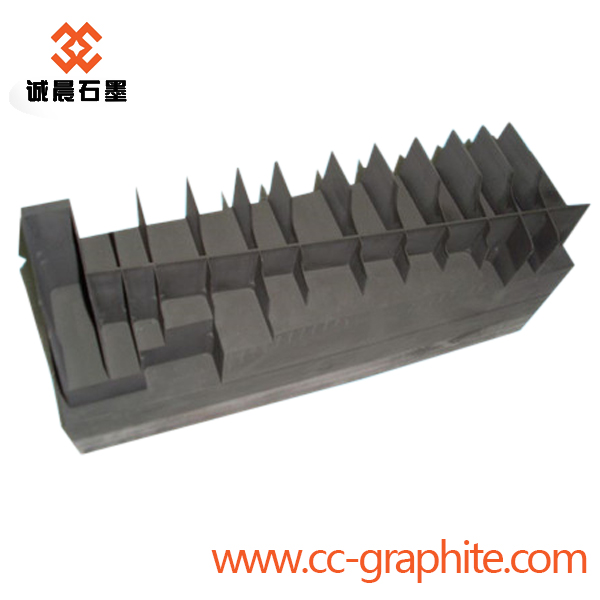

- Electric Discharge Machining

- Semiconductor and Photovolatic Industry

- Optical Fiber Industry

- graphite crucible for Leco

- graphite lubricant for guide pin. guide bush.

- flexible graphite gasket

- graphite/PTFE packing

- Equipment

- Inquiry Now

- Contact

English

English 中文

中文