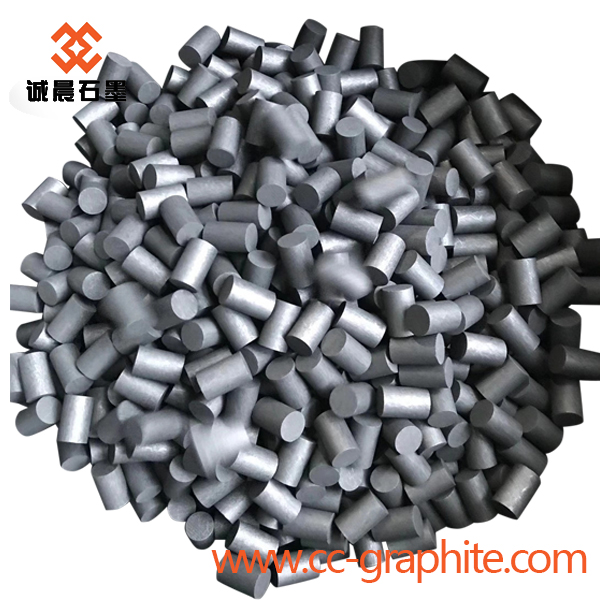

graphite lubricant for guide pin. guide bush.

Inquiry This Item

Graphite lubricant, also known as graphite pillars, can also be referred to as small-sized graphite rods, graphite particles, etc. Their names may vary depending on the industry they are used in. However, their products are all the same and require processing with high-purity lubricating and conductive graphite. There are two main manufacturing methods for lubricating and conductive graphite particles: one is to use graphite powder and adhesive to stir and extrude. These graphite particles are very soft and have low compressive strength, greatly reducing the conductivity effect because they contain a large amount of adhesive. The other type of graphite column mainly comes from mechanical processing of graphite electrodes, using high-quality graphite raw materials through CNC lathe control cutting.

Due to its conductivity, thermal conductivity, high temperature resistance, low ash content, high carbon content, and good chemical stability, graphite columns are widely used as carburizing agents in steelmaking furnaces, reducing agents in chemical industries, and as one of the important raw materials for producing carbon blocks for aluminum production. It can also be used on guide sleeves, guide pillars, self-lubricating bearings, and wear plates.

Specifications of graphite lubricant,

small diameter: 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm

13mm, 14mm, 15mm, 16mm, 18mm, 20mm, 22mm, 25mm, 30mm,

Large diameter: 100mm, 150mm, 200mm, 300mm, 320mm, 400mm, 420mm

Technical date sheet:

Density: 1.72-1.75

Resistance: 5-6 ohms

Particle: 0.8

Bending strength:>13 MPA

Compressive strength:>32 MPA

Ash content:<0.2%

English

English 中文

中文